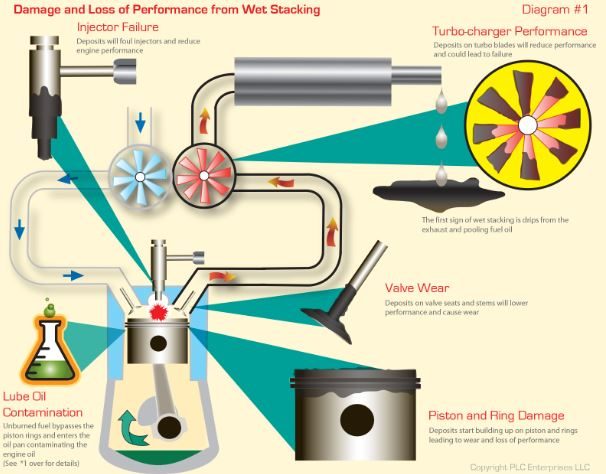

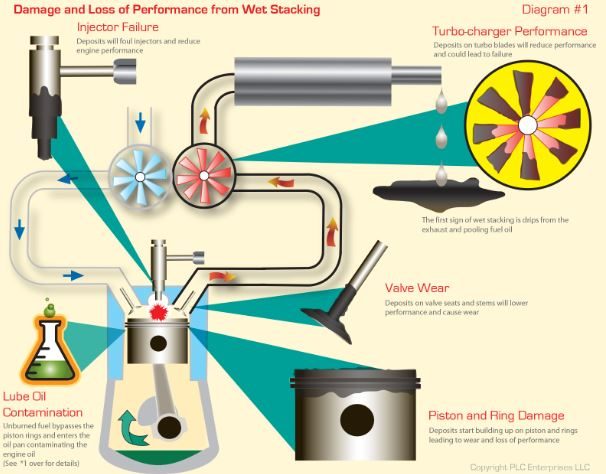

When diesel generators are operated at no or light load for extended periods of time, a dark, thick liquid will begin to drip from the exhaust system. This dripping substance negatively affects the operation of your generator, and is commonly known as "wet-stacking."

The mechanical workings of a diesel engine can be complicated, so understanding why wet stacking occurs (and how to prevent it) can be somewhat difficult. So first, let's start with the basic function of your diesel engine.

Basics of a Single Cylinder 4-Stroke Diesel Engine

- The intake stroke. The piston moves downwards, and in response, the intake valve opens. Now the turbocharger can deliver compressed air into the cylinder.

- Compression stroke. When the piston can't move any farther, it reverses its direction and begins moving back upwards. This causes the intake valve to close, and the piston compresses the air left in the cylinder. At this point, the temperature and pressure of the air raises significantly.

- The fuel injection. When the piston reaches the top of its compression stroke, the fuel injector dispenses a mist of fuel into the cylinder. The hot air in the cylinder vaporizes and ignites the fuel. The now burning fuel adds even more heat to the cylinder, and the pressure and temperature continues to rise.

- Power stroke. Hot compressed gas pushes the piston down. Through your engine's tie rod, the piston's force is transferred to the crankshaft and causes it to turn.

- Exhaust stroke. In the final step, the exhaust valve will open. The piston pushes hot gas out of the cylinder, through the exhaust valve, and into the exhaust system. Some of the exhaust gas is intercepted by the turbocharger in order to drive the compression of the intake air so the cycle can start over.

So what happens in wet stacking?

When your generator is run at light or no load, the inside of the engine is significantly cooler than when operated at higher loads. Since the cylinder cannot reach its peak temperature, there is not enough hot compressed air to vaporize and ignite the fuel. Fuel will still light and burn, but it will leave small, hard particles of unburned carbon – the vaporized fuel and soot that couldn't be burned completely.

Inside your exhaust system, these vapors will combine with the soot, forming the thick dark liquid that can be mistaken for engine oil. Look for this liquid in two places: the turbocharger and exhaust outlets.

In addition to this leaking liquid, the soot may also form hard carbon deposits on the fuel injector nozzle inside the cylinder. As part of step 3 above, this nozzle must be able to spray a fine mist into the cylinder. When the nozzle is covered in these carbon deposits, it cannot as effectively atomize the fuel and instead will deliver larger droplets into the clyinder that can't be readily vaporized. This means that more fuel goes unburned and more fuel passes into the exhaust system. Wet stacking occurs progressively in this pattern and will eventually lead to permanent engine damage.

**reposted from http://www.pennenergy.com/articles/pennenergy/2016/04/maintaining-healthy-power-systems-ensuring-generator-longevity.html

Negative Consequences of Wet Stacking

- Expense: Excessive wet stacking shortens the life of your engine, resulting in premature (and costly) replacement.

- Pollution: Many urban areas limit smoke emission levels which are produced by wet stacking.

- Power: The carbon deposits that occur because of wet stacking affect the engine's maximum power rating. An engine affected by wet stacking will operate at a lower power than it was designed to achieve.

- Maintenance: An engine affected by wet stacking will require much more maintenance than one that is appropriately exercised.

The Solution to Wet-Stacking

Rather than exercising your diesel generator with a light or no load at all, experts recommend that operators run their generators for a few hours at at least 75% load in order to avoid wet stacking. Operating your generator at this load allows the engine to reach the appropriate temperature needed to effectively burn the fuel entering your system.